Optimal Timing for Asbestos Abatement

Asbestos abatement is most effectively performed during periods of minimal occupancy to reduce exposure risks. Scheduling during warmer months can facilitate better ventilation and drying, aiding in the safe removal process. Additionally, planning during times of low construction activity minimizes disruptions and ensures compliance with safety protocols.

Spring and summer months are ideal for asbestos abatement due to favorable weather conditions that support ventilation and containment.

Scheduling during periods of low occupancy reduces risk to occupants and simplifies containment procedures.

Dry, mild weather helps prevent moisture buildup, which can complicate removal and increase health risks.

Timing abatement projects to align with local regulations ensures safety standards are maintained and inspections are streamlined.

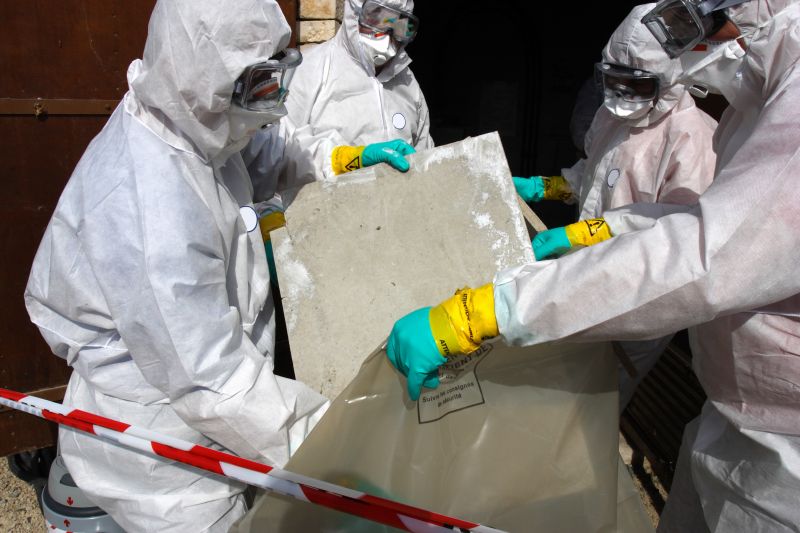

Workers carefully removing asbestos-containing materials in a controlled environment.

Proper gear is essential for safety during asbestos removal procedures.

Containment barriers prevent asbestos fibers from spreading to other areas.

Ways to make Asbestos Abatements work in tight or awkward layouts.

Popular materials for Asbestos Abatements and why they hold up over time.

Simple add-ons that improve Asbestos Abatements without blowing the budget.

High-end options that actually feel worth it for Asbestos Abatements.

Finishes and colors that play nicely with Asbestos Abatements.

| Factor | Impact on Timing |

|---|---|

| Weather Conditions | Mild and dry weather facilitate safer removal |

| Occupancy Levels | Lower occupancy reduces health risks |

| Regulatory Deadlines | Compliance may dictate specific scheduling |

| Project Scope | Larger projects may require longer planning |

| Availability of Contractors | Scheduling depends on contractor availability |

Asbestos abatement is a complex process that requires careful planning and execution to ensure safety and compliance. The timing of abatement projects can significantly influence their success, safety, and cost. Proper scheduling considers seasonal weather patterns, occupancy levels, and regulatory requirements to optimize results. It is essential to coordinate with experienced professionals to determine the most suitable window for each project, minimizing risks and disruptions.

Specialized tools used to safely extract asbestos materials.

Personnel equipped with protective clothing during abatement.

Properly sealed areas prevent fiber escape during removal.

Final checks ensure all asbestos has been safely removed.

Little measurements that prevent headaches on Asbestos Abatements day.

A 60-second routine that keeps Asbestos Abatements looking new.

A frequent mistake in Asbestos Abatements and how to dodge it.

Small tweaks to make Asbestos Abatements safer and easier to use.

Interested parties should consider scheduling asbestos abatement during optimal seasons to ensure safety and compliance. Proper timing supports effective removal, minimizes health risks, and reduces project costs. For further information or to discuss scheduling options, it is recommended to contact qualified professionals experienced in asbestos abatement procedures.